The Advantages Of Corrosion Monitoring

We offer a wide range of corrosion monitoring services based on our unique experience, knowledge and equipment. We provide the following:

1. Selection and supply of corrosion monitoring units;

2. Corrosion monitoring services;

3. Installation supervision. On-site installation of the proposed monitoring systems;

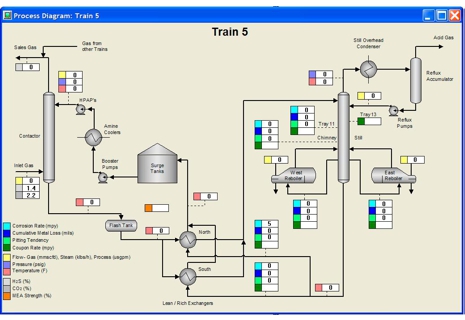

4. Pre-commissioning. Connection of our equipment to the clients’ DCS, adjustment of signals and automated devices, commissioning;

5. Processing and analysis of the data received. Remote technical support, as well as on-site visits;

6. Personnel training. Theoretical and practical courses on working with equipment, data collection and processing.

The Proposed Corrosion Monitoring Methods

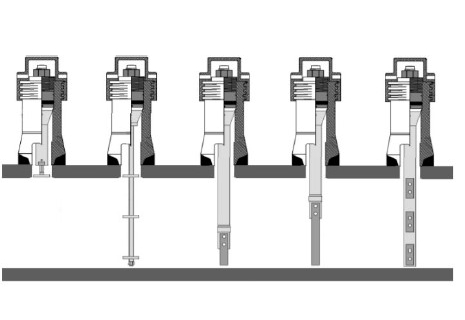

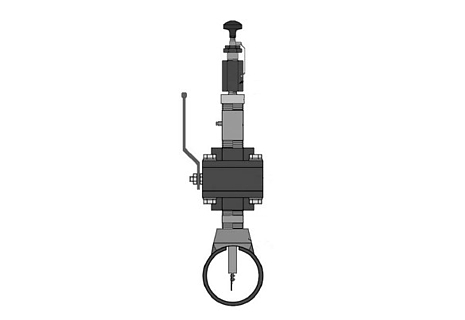

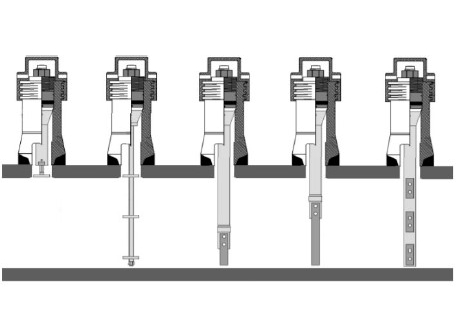

Gravimetric system

It is a conventional method based on determining the weight loss of metal specimens during their exposure to a test medium.

GRAVIMETRIC SYSTEM

GRAVIMETRIC SYSTEM

GRAVIMETRIC SYSTEM

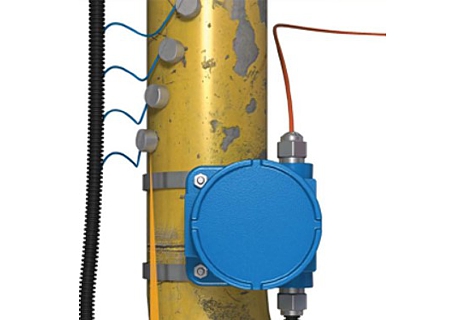

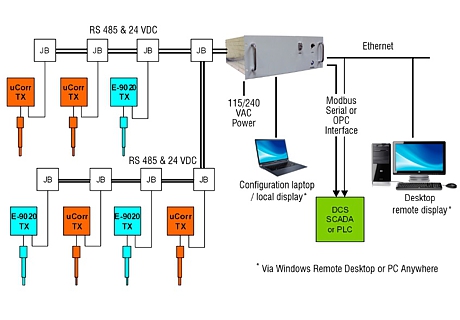

ER and LPR systems

Corrosion rate monitoring based on the electrical resistance (ER) method provides the measurement of the corrosion rate of any metallic equipment or structure. The ER method can evaluate both electrochemical and mechanical effects.

The Linear Polarization Resistance (LPR) method is especially useful to quickly detect corrosion and promptly take technical corrective actions, thus prolonging equipment life and minimizing unplanned downtime.

ER AND LPR SYSTEM

Er and lpr system

ER AND LPR SYSTEM

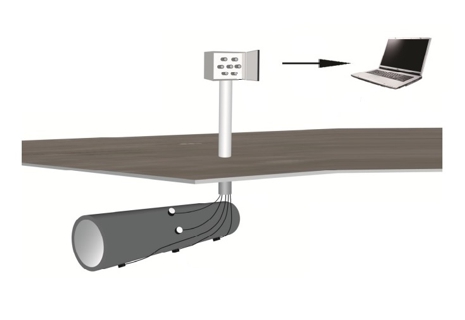

Ultrasonic system

The ultrasonic erosion and corrosion monitoring system for above-ground and underground pipelines provides easy installation and convenient operation. The system is installed outside a pipeline and does not interfere with maintenance check inside the pipeline.